A Tangle Free Rope Storage

Solution for Rock Climbers

Problem

Create a storage solution for rock climbing

rope that prevents tangles and is easy to use.

Solution

Wrapped, a rope storage device that securely

holds rope without twists and tangles.

Design Constraints

To be useful for rock climbing, a rope holder must be able to carry a suitable length of rope that allows for most routes to be safely accessible. One of the most common lengths of rope that will allow the climber to climb most routes they encounter is 60m. This not only covers the height needed to reach the top, but also the amount of rope needed to be safely lowered to the bottom by a spotter.

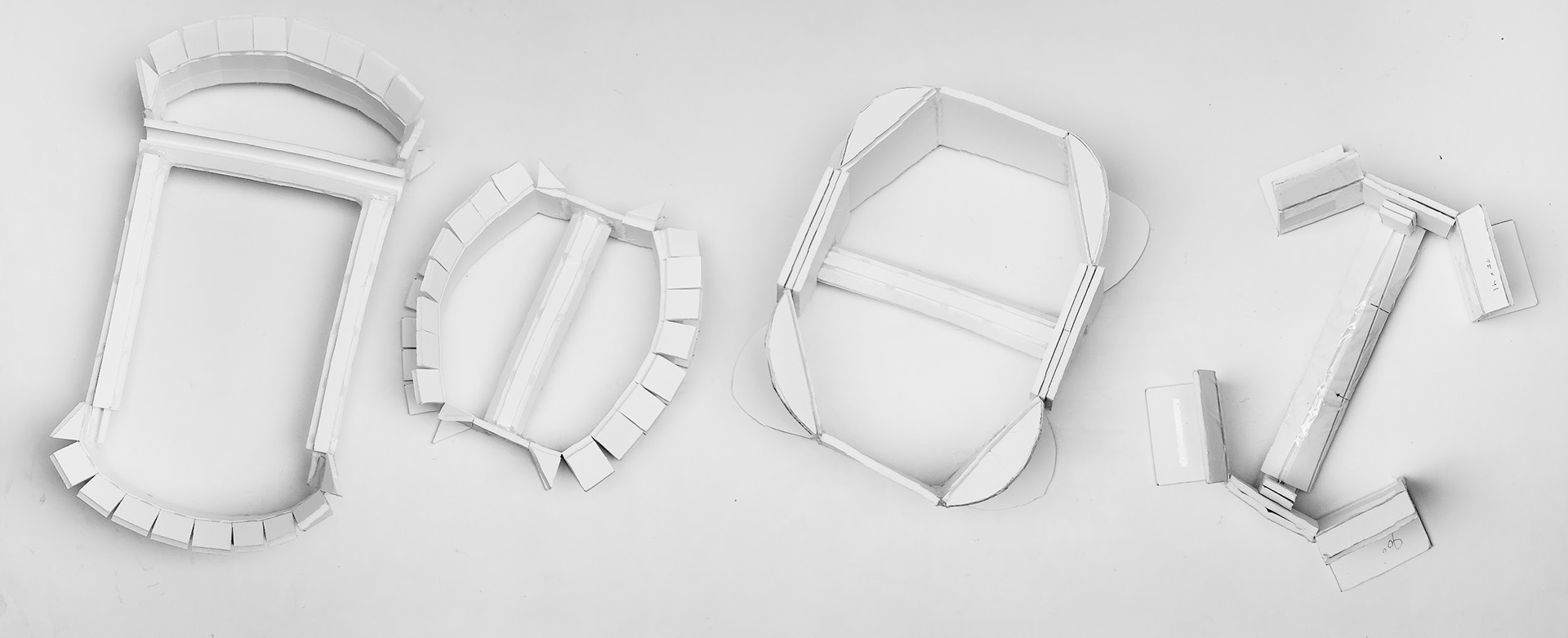

Form Exploration

During the course of the design process, it quickly became clear that constraining the ideation process to paper would not be practical. On paper, it is impractical to try to figure out if a particular design would hold 60m of rope without risk of sliding off. Prototyping in foam core allows not only for ergonomics testing, but also the ability to run a handful of tests wrapping rope around the model before it is too weak to no longer support the weight of the rope. Physical prototyping led to the most significant changes in the design, specifically in relation to the ergonomics and the rope track. Initially, Wrapped was intended to be slotted along the user's forearm, this posed significant ergonomic problems when faced with uniquely capable user groups. Switching to a simply grip allowed for a larger user group to be able to properly use the device without limiting the intended function. Splitting the rope track allows for the simplification of production, requiring fewer materials and less complex bends, without compromising storage capacity.

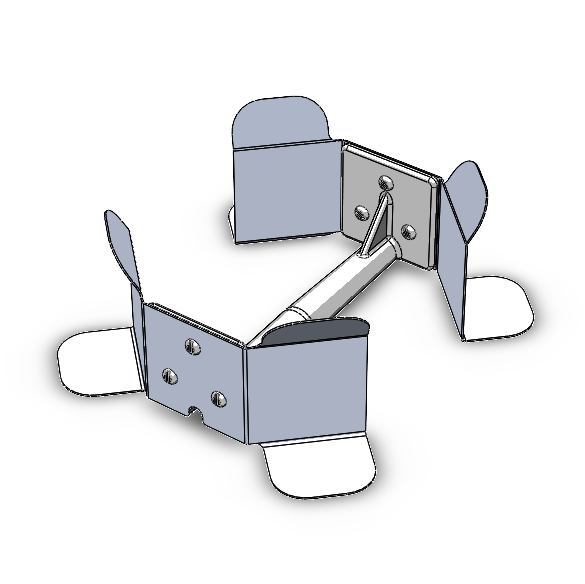

Digital Modeling

Using SolidWorks, final tweaks to the design were made in consideration to manufacturing constraints. The goal of this process was to minimize the amount of unique parts and materials to cut down on manufacturing and material costs. With only three unique parts and two unique materials, Wrapped is specifically designed for mass production without the overhead that would come with more complex designs that utilize more unique parts and materials.

Final Prototype

As a final prototype, the same materials that would be using in the mass production of Wrapped were used as a final test of the design. Though the manufacturing process differs from what would be possible with mass production, using the same materials provides insight into how the final product would perform. The rigidity and durability of the aluminum rope track, nylon binding screws, and 3D printed nylon handle proved to be more than enough to handle 60m of rope.

Branding

The logo and branding treatment for Wrapped was intended to reflect the design of the final product. Squeezing the text with a dashed purple line invokes the image of rope being wrapped around Wrapped. The name, while on the nose, is an accurate descriptor of what the product does while still being somewhat catchy and easy to remember.